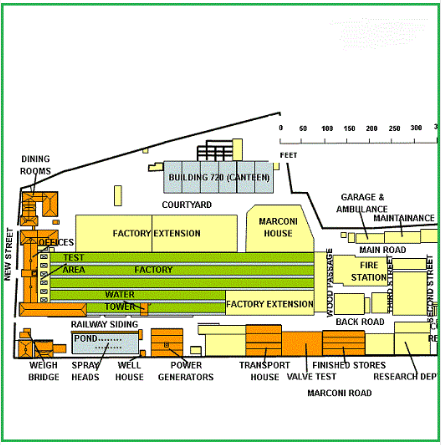

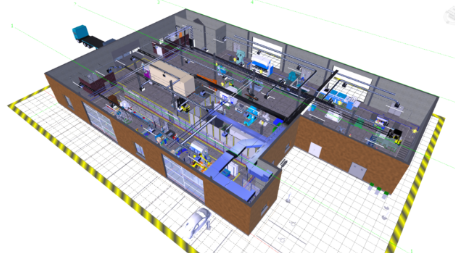

Factory & Facilities Layout

Manufacturing process layouts are an important focus in Lean organizations because they are often full of inefficiencies that lead to wasted time, effort and materials.

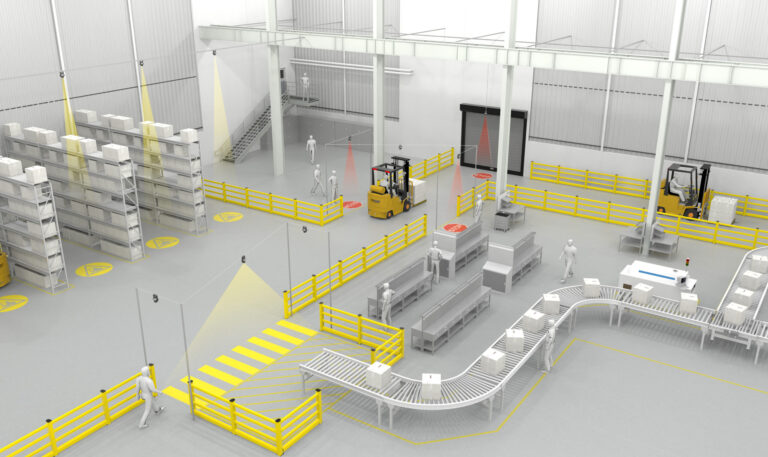

The basic objective of layout is to optimize flow of Work, Material, Customers and Information through the system now and in the future. The plant layout- design is a very critical part of running an efficient and cost effective business which is very important for Plant optimization.

So, the key goal of the of consultants when design a new Factory layout design or updating an existing factory layout is plant optimization

Factory layout design is driven not only by the needs for the present business levels but should also have provisions for future expansion, variety of competing demands should also be considered in factory layout design based on strategic business plan and long term objectives.

Strategic business plan and capacity study, are the first step, The second step in rethinking a manufacturing layout is collecting data about the existing process. Information such as machine load, takt time, equipment reliability, set-up time, yields, and staffing requirements are necessary inputs for redesigning process layouts. This can include historic capacity such as number of units per shift or units per hour. Individual machines-new machines required will evaluate for their theoretical capacity based on the maximum speed or other equipment to achieve the required production and quality objectives based on the strategic business plan.

- Reduce operating costs

- Minimize Material handling costs

- Utilize Space efficiently

- Utilize Labor efficiently

- Eliminate Bottlenecks

- Reduce manufacturing Cycle Time and customer service time

- Eliminate wasted or Redundant Movement

- Facilitate the Entry, Exit, and Placement of Material, Products, and People

- Incorporate Safety and Security measures

- Promote product and service Quality

- Encourage proper Maintenance activities

- Provide a visual Control of Operations or activities

- Provide Flexibility to adapt to changing conditions

- What a facility is, what a layout is, types of layouts.

- How to balance an assembly line.

- How to design a process layout.

- How to gather information to design a layout.

- How to design a product layout.

- How to use AutoCAD in your layout design process.

- Work shop for factory layout design.

A two-days session

-This course is designed for managers, supply chain managers & planners, process improvement specialists, change managers, process engineers, quality manager & production engineers.