Kanban Material Management

This course will teach the implementation of a lean pull system for purchased parts that ensures that purchased parts are delivered to manufacturing cells efficiently and timely. Attendees will learn how to develop and use a system for planning parts, how to setup purchased parts supermarkets, how to implement kanban, and how to effectively deliver purchased parts to manufacturing cells Using a case example, participants will make calculations and design a system for handling purchased parts.

- Lower inventory and increased productivity

- Elimination of operator time retrieving/finding parts

- Higher plant inventory turns

- Fewer inventories

- Increased safety

- Reducing waste &Scrape

- Reducing PPM

- Reducing material Damage

- Material and product control.

- Improving work place Organization

- Improving lead time deliver

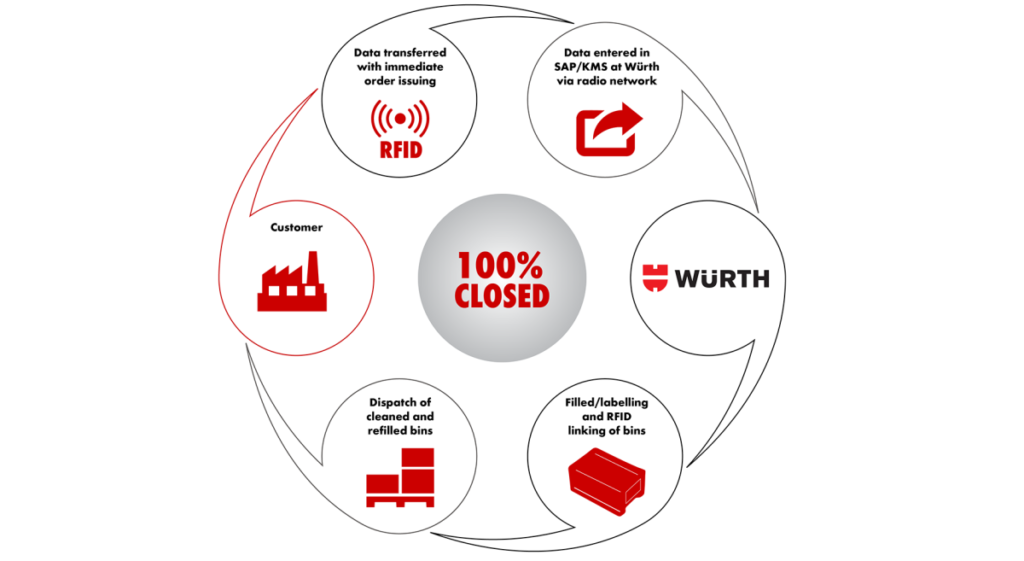

- Lean Overview/Kanban Systems

- origins of kanban systems

- Benefits

- Kanban types

- Kanban signals

- Kanban visual board

- Material movement within a Facility

- When and where to begin implementation

- Purchased Parts Market

- Sizing/Storage Requirements

- Balancing the process

- Setting/Specifying/Managing Inventory Levels

- Pull Signals

- Hijunka Box

- Part Movement/Material Handling

- Exercise

- Standardized Work

- Calculating Kanban

- Exercise

A Three-days session

-This course is designed for managers & supervisors, supply chain managers & planners, process improvement specialists, change managers, process engineers, quality manager & production engineers.