Total Productive Maintenance (TPM)

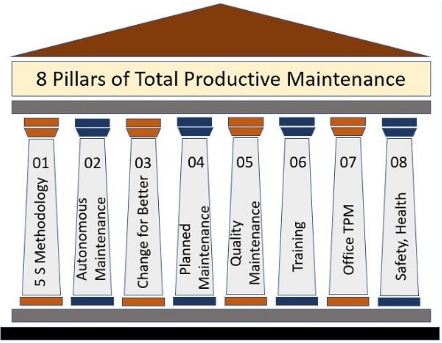

The Total Productive Maintenance (TPM) training certification course covers the essential aspects of a TPM program. It includes programs like the seven pillars of TPM, and the benefits and objectives of the TPM program. Start the course and learn about measuring performance in a TPM program, , and the types of maintenance and reliability centered maintenance

- Maintain equipment in good working condition

- Extend equipment working life by slowing deterioration

- Develop employee skills to operate and maintain equipment competently

- Ensure safe operation and servicing of equipment by employees

- Ensure equipment is able to function in all areas critical to quality

- Reduce machine downtime due to equipment maintenance and repair

- Guide the organization to select/modify equipment to match their operational needs

- Improved Productivity / Equipment Uptime

- Improved Quality

- Improved Ability to Respond to Customer Needs.

- Reducing non-conforming products

- Reducing material damage

- Reducing scrape

- Improving PPM

- Reducing raw material Inventory

- Reducing FG inventory

DAY 1

- Introduction to TPM

- What is lean

- Value added and non value added.

- Types of waste in processes.

- Lean tools and techniques

- Kaizen &GEMBA

- What is TPM.

- AM&PM

- TPM KPI’s( OEE- MTBF-MTTR…)

- TPM Deployment structure

- TPM Assessment

DAY2

- TPM Pillar 1-5S

- KAIZEN 5S

- 5S- Workshop

- TPM Pillar 2- TEAMS

- TPM Pillar 3- AM

- Workshop

- Assign Projects.

DAY3

- TPM Pillar 4- PM

- Workshop

- Kaizen Projects

- TPM Pillar 5 Effective Maintenance

- TPM Pillar 6 –Focus Improvement

- TPM KPI’s

- Quality Tools& PSP

- Review Kaizen TPM Projects

DAY4

TPM Pillar 7 –Quality Maintenance

TPM Pillar 8 -Training and education

TPM Pillar 9 -Early management

TPM Pillar 10 SHE

TPM Pillar 11 TPM –in Admistration

TPM -Spare parts inventory management

Review Kaizen TPM Projects

DAY5

Review Kaizen TPM Projects

Final TPM Assessment

A Three-days session

-This course is designed for manufacturing and plant managers, production control managers and supervisors, materials managers and analysts, manufacturing and industrial engineers & industrial managers.